Happy to help !

Depending on the application 5,3, or 2HP would work.

Will show Model 516 as example;

* produces 3 GPM @ 713 RPM, 2HP when pressure is set to 1000 psi.

* produces 3 GPM @ 713 RPM, 3HP when pressure is set to 1500 psi.

* produces 4 GPM @ 950 RPM, 3HP when pressure is set to 1100 psi.

* produces 4.5GPM @ 1070 RPM, 3HP when pressure is set to 1000 psi.

* produces 5 GPM @ 1200 RPM, 3HP when pressure is set to 900 psi.

* produces 4 GPM @ 950 RPM, 5HP when pressure is set to 1850 psi.

* produces 4.5GPM @ 1070 RPM, 5HP when pressure is set to 1650 psi.

* produces 5 GPM @ 1200 RPM, 5HP when pressure is set to 1500 psi.

Re; pressure & nozzle size;

Pressure is created by restriction of the pumped water flow through the spray nozzle(s).

No nozzle(s) or oversized nozzle(s) = Reduced or no pressure.

Pressure is controlled by a pressure regulator (or unloader).

Water delivered from the pump, which is not needed to meet a set pressure, is bypassed through the pressure regulator (or unloader).

Note water flow & size nozzle(s).

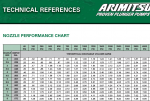

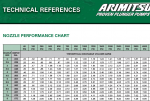

Water flow through a nozzle with vary with pressure, refer to Nozzle Performance Chart.

examples;

#5 nozzle passes 2.5 GPM when pressure is set to 1000 PSI.

#5 nozzle passes 5 GPM when pressure is set to 4000 PSI.

#6 nozzle passes 3 GPM when pressure is set to 1000 PSI.

#6 nozzle passes 6 GPM when pressure is set to 4000 PSI.

Insure correct Motor RPM and pulleys.

Electric Motor RPM, Electric motor pulley diameter, & Pump pulley diameter determine Pump RPM.

Pump RPM determines its flow produced.

Helpful tutorial here pertaining to nozzles, HP, & pulleys;

arimitsupumps.com

* click "technical tips"

Happy to help !

Greg @ Arimitsu Pumps