Car Wash Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

18 guage wire connector selection

- Thread starter 1carwash1

- Start date

OurTown

Well-known member

Is it a large junction box and do you have a lot of wire to play with? If it is an area that might get wet and you don't mind it being a permanent connection then I say solder and heat shrink. Crimp butt connectors work great for me but just make sure you get a good crimper. I bought the Klein 3005CR and it works great and is stocked by most Home Depot stores. If you think you don't want permanent connections and it won't get wet then use a Wago 221 series. I love those things but they are large and pricey but are awesome for things like coin mechs.

Earl Weiss

Well-known member

Don't know if it's a great idea but when I wanted to use them for small gauge wire I twisted the wires together and put them thatway in a single slot - so far so good.. It would be nice if they made one of those inline connectors that went down to 24 gauge wire for coin mechs and Cryptopay swipers.

OurTown

Well-known member

Don't know if it's a great idea but when I wanted to use them for small gauge wire I twisted the wires together and put them thatway in a single slot - so far so good.

If you get the right ones they go down to 24 gauge which is the smallest wire I see at car washes. I have tried that trick before because it worked better on some. It could have been because I accidently stripped some of the wire strands effectively making it a smaller gauge. (I have a hard time stripping those tiny wires properly)

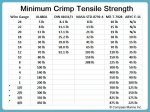

For long term connections I use butt splices. Good butt splices and a good crimper makes a huge difference in the quality of the connection. A good crimp should survive a pretty significant pull test. I ran across an article years ago and IIRC red butt splices should be able to survive a 10 lb pull. Yellow crimps should survive 25lb plus pull test. I'll try to find that article and post a link.

They don't sell any good splices at the local hardware stores. You can find them at electrical supply houses and online. I use 3M nylon butt splices.You can see through the jacket of a nylon insulated butt splice and the good ones are likely .25-.50 each.

As far as tools, I've bought some dedicated ratcheting crimpers with interchangeable dies and they are good for heavily involved projects where tons of crimping is done, but they don't last long in my toolbag before they are removed for a more space efficient tool. Klein makes the 1005 and they are some of the best "multi tool" type crimpers that also serve as wire cutters. They do have a newer model that has a built in stripper and they seem to crimp OK too, they are just not finished as well. I just put a set of snap on crimpers in my bag but they are very similar in design to the klein 1005s, except they have the insulated crimp closer to the end.

They don't sell any good splices at the local hardware stores. You can find them at electrical supply houses and online. I use 3M nylon butt splices.You can see through the jacket of a nylon insulated butt splice and the good ones are likely .25-.50 each.

As far as tools, I've bought some dedicated ratcheting crimpers with interchangeable dies and they are good for heavily involved projects where tons of crimping is done, but they don't last long in my toolbag before they are removed for a more space efficient tool. Klein makes the 1005 and they are some of the best "multi tool" type crimpers that also serve as wire cutters. They do have a newer model that has a built in stripper and they seem to crimp OK too, they are just not finished as well. I just put a set of snap on crimpers in my bag but they are very similar in design to the klein 1005s, except they have the insulated crimp closer to the end.

Old Post I know but I ran across that article referenced above and snatched the table out of it. As you can see pull strength on 12 gauge should be at the least 35lbs, and mil spec says it should pretty much survive 100lbs plus. This chart implies a quick, light, tug on the wires is not an adequate test of the quality of the crimp, especially heavier gauges crimps. I have tried this with good crimpers and cheap crimpers, as well as inexpensive butt splices and can verify that there is a huge difference in crimp strength. I would suggest playing with the crimpers and butt splices you use now and see if they make an adequate crimp. The ABYC E-11 referenced in the chart is the American Boat and Yachting Council Standard.

https://marinehowto.com/marine-wire-termination/ for those that want to read the article

https://marinehowto.com/marine-wire-termination/ for those that want to read the article

Last edited:

MEP001

Well-known member

Last I checked the 3M insulated butt splicers had gotten crazy expensive, like 70¢ each. I switched to Amp, which were still 15¢ last time I ordered.

The 3M are made with a rolled metal interior, and sometimes they open up when you crimp. I had gotten used to looking down in the barrel to make sure the butted ends get flattened together in the crimper, otherwise they may open up and let the wire slip out. The Amp insulated butt splicers are a lot more forgiving.

The 3M are made with a rolled metal interior, and sometimes they open up when you crimp. I had gotten used to looking down in the barrel to make sure the butted ends get flattened together in the crimper, otherwise they may open up and let the wire slip out. The Amp insulated butt splicers are a lot more forgiving.