Hoping I can get some advice on new to me pump stand I’m putting together.

Original stand is rusted, messy wiring, motors need rewound and all pumps need rebuilt or replaced, it is also only single phase.

Picked up an used stainless proline stand with Baldor 3 phase motor and installed new Arimitsu pumps.

Now to the questions, the original stand has check valves on the water supply inlet to the pump. I bought check valves for the new stand, but looking at it, I don’t believe it needs check valves. Gravity fed water tank with hydrominders. I run Paraplate bypass regulators with weep nozzles, so in my mind the pumps always using more water than it’s recircing so it would never pressurize the suction? Is there any other tricks other than just throttling the water supply to get hp chemicals to flow?

Also removed all the solenoids from proline stand. All my LP functions mounted on the wall. I will need 2 solenoids per pump for HP functions. Any preferences on solenoids? Used to like dema but have had many small solenoid failures, use a lot of asco red hats at work so I’ve been using those recently with much success.

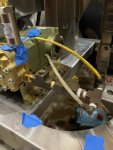

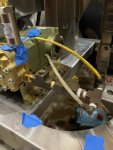

couple pics of different mounting options

Original stand is rusted, messy wiring, motors need rewound and all pumps need rebuilt or replaced, it is also only single phase.

Picked up an used stainless proline stand with Baldor 3 phase motor and installed new Arimitsu pumps.

Now to the questions, the original stand has check valves on the water supply inlet to the pump. I bought check valves for the new stand, but looking at it, I don’t believe it needs check valves. Gravity fed water tank with hydrominders. I run Paraplate bypass regulators with weep nozzles, so in my mind the pumps always using more water than it’s recircing so it would never pressurize the suction? Is there any other tricks other than just throttling the water supply to get hp chemicals to flow?

Also removed all the solenoids from proline stand. All my LP functions mounted on the wall. I will need 2 solenoids per pump for HP functions. Any preferences on solenoids? Used to like dema but have had many small solenoid failures, use a lot of asco red hats at work so I’ve been using those recently with much success.

couple pics of different mounting options