Roz

Well-known member

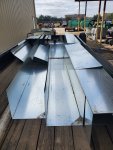

starting a rehab project where the self service bay lines are just lying in the attic unprotected. I can only imagine how they faired in the winter months. Has anyone come across a prefab insulated troth for the bay hoses? Otherwise I will find a carpenter to build us the insulated box. Thx