Recognize this RO brand/brine valve?

- Thread starter slash007

- Start date

bobcat9095

Member

Power Head Fleck 9500 Econominder-3460413-95PH (softenerparts.com)

This is what it looks like it is.

This is what it looks like it is.

MEP001

Well-known member

Definitely a 9500 if it's 1-1/2" which it looks like, if it's 1" it's a 9000.

Make sure you get the same range and brine valve.

What's wrong with it? I've repaired many of them with new seals. I've only had one that was washed out and had to be replaced.

Make sure you get the same range and brine valve.

What's wrong with it? I've repaired many of them with new seals. I've only had one that was washed out and had to be replaced.

slash007

Well-known member

Found brine tank overflowing, but then it stopped on it's own. Figured I'd get new seals if rebuildable or a new one if not and go ahead and fix it. Should be easy to change seals, I'll order those. Best place to buy the seals? Appreciate the information. Thanks guys.Definitely a 9500 if it's 1-1/2" which it looks like, if it's 1" it's a 9000.

Make sure you get the same range and brine valve.

What's wrong with it? I've repaired many of them with new seals. I've only had one that was washed out and had to be replaced.

MEP001

Well-known member

You can get all the parts from softenerparts.com.

For the brine tank to overfill, you have at least two problems:

The brine tank usually has a valve to prevent it from overfilling. If it has one, it's bad.

And:

The brine valve (in your second picture above) could be bad and allowing the tank to slowly overfill, easily checked by disconnecting the brine line to the tank,

Or:

The upper seals and spacers are either bad or have gotten misaligned from the spacers collapsing, which will usually cause it to slowly fill the brine tank instead of drawing brine during that cycle.

The power head linked above is not the entire head. It will not fix your problem.

For the brine tank to overfill, you have at least two problems:

The brine tank usually has a valve to prevent it from overfilling. If it has one, it's bad.

And:

The brine valve (in your second picture above) could be bad and allowing the tank to slowly overfill, easily checked by disconnecting the brine line to the tank,

Or:

The upper seals and spacers are either bad or have gotten misaligned from the spacers collapsing, which will usually cause it to slowly fill the brine tank instead of drawing brine during that cycle.

The power head linked above is not the entire head. It will not fix your problem.

slash007

Well-known member

Hmm. I did disconnect the brine line and no water was coming out, so not an issue there unless it's intermittent. I'm pretty sure this site doesn't have a valve in the float tank, but I'll double check. That leaves the upper seals and spacers. Where are those exactly?

MEP001

Well-known member

In the head behind the plate. They're really easy to access, but it can be a pain to get the surfaces clean for new seals.

IMO it's more likely that the brine valve in the head is sticking or had debris caught in it.

IMO it's more likely that the brine valve in the head is sticking or had debris caught in it.

slash007

Well-known member

I am low on resin and starting to get harder water. I'm up to 3 grains now. I was thinking that if I low the capacity, it would regenerate more often to make up for the low resin and give me soft water for now . Does it work like that? If so, looking at the first photo (1st post), what adjustments do I need to make to the dial on the top left in order to do so? I read the manual but am not sure I understand it 100% Thanks.I need to replace a brine valve at another site and was wondering if anyone recognized this brine valve or RO system and could direct me to the best place to buy the valve? Thanks. View attachment 6979 View attachment 6980

MEP001

Well-known member

The reason you're low on resin is because it breaks down and flows out during the backwash cycle. Right now it's set for 5500 gallons to regenerate. Pull out on the center of the dial to lower the gallons. IMO that's not going to help, you'll just waste water and salt.

slash007

Well-known member

Anything else that would cause my hardness to get higher? Or does it have to be the resin? Salt tank is full and seems to be working properly.The reason you're low on resin is because it breaks down and flows out during the backwash cycle. Right now it's set for 5500 gallons to regenerate. Pull out on the center of the dial to lower the gallons. IMO that's not going to help, you'll just waste water and salt.

Greg Pack

Wash Weenie

Manually regenerate and see if your hardness goes to 0.

As far as problems-Check to see if you're incoming hardness has changed. Also make sure your flowmeter is working. Chlorine breaks down resin. I have one wash where I had to change out resin in less than five years after new installation.

I like the fleck nxt head control, but I don't know how to work on softeners so am prone to swap out instead of servicing.

As far as problems-Check to see if you're incoming hardness has changed. Also make sure your flowmeter is working. Chlorine breaks down resin. I have one wash where I had to change out resin in less than five years after new installation.

I like the fleck nxt head control, but I don't know how to work on softeners so am prone to swap out instead of servicing.

slash007

Well-known member

To manually regenerate, do I just turn the black dial one click to the right?

MEP001

Well-known member

Just nudge it off the stop. If you aren't careful or if it's noisy and you can't hear the clicks, you can easily push it past the first set of pins and the whole regeneration process gets thrown off. If you turn it slowly until the gears start to move, you've already turned it too far.

I recommend you check it every day. Test the hardness and write it down, and look to see which tank it's on. You can see it on the right side of the lower gear shaft. You should track it so you can tell if one tank is sending out harder water than the other. That will absolutely confirm if the problem is with the resin or with the head.

Edit: Just noticed in the picture that the upper piston rod link is not in its proper spot. That could cause issues with one tank not getting brined properly.

I recommend you check it every day. Test the hardness and write it down, and look to see which tank it's on. You can see it on the right side of the lower gear shaft. You should track it so you can tell if one tank is sending out harder water than the other. That will absolutely confirm if the problem is with the resin or with the head.

Edit: Just noticed in the picture that the upper piston rod link is not in its proper spot. That could cause issues with one tank not getting brined properly.

slash007

Well-known member

I checked my hardness yesterday and it was 30. I'm hoping I just messed up a regen cycle while messing with it a few days ago, but had it switch tanks and did a proper regen and will test again today. Here are a couple more photos of the head. I'm not sure I see what's wrong with the upper piston rod? Here is a side view photo if it helps. Thank you.Just nudge it off the stop. If you aren't careful or if it's noisy and you can't hear the clicks, you can easily push it past the first set of pins and the whole regeneration process gets thrown off. If you turn it slowly until the gears start to move, you've already turned it too far.

I recommend you check it every day. Test the hardness and write it down, and look to see which tank it's on. You can see it on the right side of the lower gear shaft. You should track it so you can tell if one tank is sending out harder water than the other. That will absolutely confirm if the problem is with the resin or with the head.

View attachment 7413

Edit: Just noticed in the picture that the upper piston rod link is not in its proper spot. That could cause issues with one tank not getting brined properly.

View attachment 7414

MEP001

Well-known member

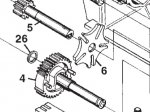

These pins

are supposed to engage these slots.

One of them isn't. You can probably push the one to the right so it does, but you'll need to either keep an eye on it or replace the gear and shaft assembly. Once you get that back in place, let it run for a few days and keep checking the hardness and the tank every day like I described earlier.

are supposed to engage these slots.

One of them isn't. You can probably push the one to the right so it does, but you'll need to either keep an eye on it or replace the gear and shaft assembly. Once you get that back in place, let it run for a few days and keep checking the hardness and the tank every day like I described earlier.

slash007

Well-known member

Thanks for your help. Just to make sure I understand correctly, am I pushing the bottom one towards the left, or pushing the top one towards the right?These pins

View attachment 7443

are supposed to engage these slots.

View attachment 7444

One of them isn't. You can probably push the one to the right so it does, but you'll need to either keep an eye on it or replace the gear and shaft assembly. Once you get that back in place, let it run for a few days and keep checking the hardness and the tank every day like I described earlier.

MEP001

Well-known member

slash007

Well-known member

I just stopped by the wash and couldn't find any pins that were sticking out the left side. The bottom gear had both flush on the left and sticking out on the right. Top gear seemed to only have one pin, unless other was hidden. It was flush on the left as well. Looking at this photo, it seems both are correct?

I tested tank 2 since it was active and hardness was 3. I did another manual regeneration and will test tank 1 tomorrow after it's had a chance to run a little. Hoping the 30 grains was due to a bad regen cycle. I still need to figure out how to get from 3 to 0 though.

I tested tank 2 since it was active and hardness was 3. I did another manual regeneration and will test tank 1 tomorrow after it's had a chance to run a little. Hoping the 30 grains was due to a bad regen cycle. I still need to figure out how to get from 3 to 0 though.

slash007

Well-known member

Tested tank one today and it was 2-3 grains hard, so the 30 had to have been caused my me messing up the regen cycle.