How are you guys attaching the elbow? Does it have to be welded? Can it be clamped?So, you saved about $30 but if you went with this you might have gained that extra length you wanted. https://www.kleen-ritecorp.com/p-38319-elbow-for-end-of-dboom.aspx

Car Wash Forum

Air logic or Air shammee

- Thread starter Hamilton's Car & Dog Wash

- Start date

Mattwash

Active member

How are you guys attaching the elbow? Does it have to be welded? Can it be clamped?

clamped it then used self tapper to hold in place. Definitely wish I would have extended the books another 2-3 feet.

Kimberly Berg

Well-known member

Hi Noob, I purchased the Mosmatic boom elbows directly from Kleen-Rite (Part #: BOMP60314). They don't swivel. You'll need to call them for current prices. 1-800-233-3873. Their elbows come with a heavy duty hose clamp, but we still welded the elbow to the Mosmastic 3' extension (Part #BOMP60315). I definitely recommend adding the 3' boom extension! Though it does add weight to the Diskin wall bracket, it takes the pressure off the hose so customers aren't pulling the hose to get it over their cars. As for the weight, we ended up adding brackets, with long screws and drilling them through the thick concrete walls.

Attachments

Kimberly Berg

Well-known member

Yes! That's the Mosmatic 2” in-line swivel coupling. I purchased it also from Kleen-Rite (Part #BOMP60323). It swivels much easier & smoother than a rubber vacuum swivel. Pricey little bugger. I paid $132.27 each 6 years ago.Thanks!

Is this a swivel that you purchased? Or are you just using a regular vac swivel.

OurTown

Well-known member

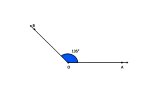

What kind of slant do I need on the boom bracket to get the boom to return to the wall?

Instructions say about 10 degrees. IIRC I mounted our brackets about 3/4" out of plumb along the sides.

I need some advice. I went mount my booms today and ran into some problems. As you’ll see in the picture my bays aren’t all that tall. I planned on mounting the booms just underneath the top of the HP hose. My problem is that I mounted the boom with about 8 degrees of lean to ensure the boom will return to the wall and in doing so the end of the boom is only about 7- 7.5 ft off of the floor. In my opinion that’s not tall enough. I drive a stock ram 2500 and at current height it will come extremely close to hitting the top of my truck. Here are the options I’ve came up with.

1-don’t use the booms and just use a straight hose.

2-I need someway to raise my HP boom. Not sure there’s an easy way to do that.

What’s your thoughts?

1-don’t use the booms and just use a straight hose.

2-I need someway to raise my HP boom. Not sure there’s an easy way to do that.

What’s your thoughts?

Attachments

edredtop

Well-known member

Go to the top block, use a large backing plate to spread the load. You'll still have room for the flex hose on the top (your plumbing looks great for it). Less tilt (tilt is overrated imho as the long hose tends to stretch over time and drags on the ground preventing complete return anyway.I need some advice. I went mount my booms today and ran into some problems. As you’ll see in the picture my bays aren’t all that tall. I planned on mounting the booms just underneath the top of the HP hose. My problem is that I mounted the boom with about 8 degrees of lean to ensure the boom will return to the wall and in doing so the end of the boom is only about 7- 7.5 ft off of the floor. In my opinion that’s not tall enough. I drive a stock ram 2500 and at current height it will come extremely close to hitting the top of my truck. Here are the options I’ve came up with.

1-don’t use the booms and just use a straight hose.

2-I need someway to raise my HP boom. Not sure there’s an easy way to do that.

What’s your thoughts?

OurTown

Well-known member

Go to the top block, use a large backing plate to spread the load. You'll still have room for the flex hose on the top (your plumbing looks great for it). Less tilt (tilt is overrated imho as the long hose tends to stretch over time and drags on the ground preventing complete return anyway.

The hose will need to be cut after a while in that height bay. I think we had to cut 3 or 4 feet off ours when we had the short ceilings.

edredtop

Well-known member

I don't think it's really matters if it's above or below the HP boom. I've never seen anybody use the dryer boom from wall to wall. I'd say max is about 135° past it's home position. Most customers figure out the extra hose quickly but there is a small group out there that could get tangled up in a ball of yarn...Are you saying to mount the boom high enough that it swings over the HP boom?

A few more things:

If needed, remember you can invert the boom to lower the location of the fasteners and raise the boom. Yeah, it looks a bit messier but if it solves a problem....

Second thing is to take note of how much the inlet on the boom swings, if I remember correctly, it was about 6 or 8" so don't get too close with your PVC or you'll create an issue where the flex hose doesn't allow for the desired movement.

I tried Vern's approach as well and it solved a problem on one of my installations. It took about an inch of shim at the base to get a result.

Putting a small stainless steel washer under the bottom of the boom between the boom and the mount (and then drop the bolt through) so the boom rides on the washer instead of the whole mount seemed to help with reducing the resistance too.

Attachments

edredtop

Well-known member

I used Schedule 80 PVC.Anybody ever connected 2” pvc to vac hose? If so how’d you do it? PVC appears to be slightly larger than the swivel. I assume you want the swivel on the outside so you can clamp it?

Duct tape for fit, and on Kim's recommendation, a carriage bolt with locking cap nut (nylon if you can get it) to keep in place if it's the customer's end of the hose.

Works well.

If it's the short flex hose that connects to the boom from the equipment room I used duct tape for fit and 3 short tap screws. I'm sure there's better ways but this has worked with no issues.

Anybody ever connected 2” pvc to vac hose? If so how’d you do it? PVC appears to be slightly larger than the swivel. I assume you want the swivel on the outside so you can clamp it?

A fernco coupling would probably work great for you.

Attachments

Last edited: